Gravity Gate Explained: What Actually Works in Real Life

The first time I came across the phrase gravity gate, it stopped me mid-scroll. It sounded serious. Technical. Almost futuristic. The kind of term that feels important even before you understand it. A few weeks later, I noticed it again – this time next to a completely different phrase: toeboards should be at least… followed by numbers, standards, and confident explanations.

That was the moment I realized how often we, especially those of us who don’t work directly in engineering or construction, encounter complex safety and technical concepts without clear context.

If you’ve ever read a safety guideline, an industrial article, or even a viral post and thought, “I get the words, but I don’t fully get the meaning,” you’re not alone. Many terms sound self-explanatory but hide layers of real-world logic underneath.

In this article, I want to walk you through gravity gate and related safety ideas in a grounded, practical way. Not as an engineer talking down — but as someone who took the time to understand what actually matters, what works, and how these concepts show up in real environments.

What Is a Gravity Gate, Really?

Here’s the part I didn’t expect: a gravity gate isn’t some abstract scientific idea. It’s very real, very practical, and very common – especially in industrial, construction, and safety-focused environments.

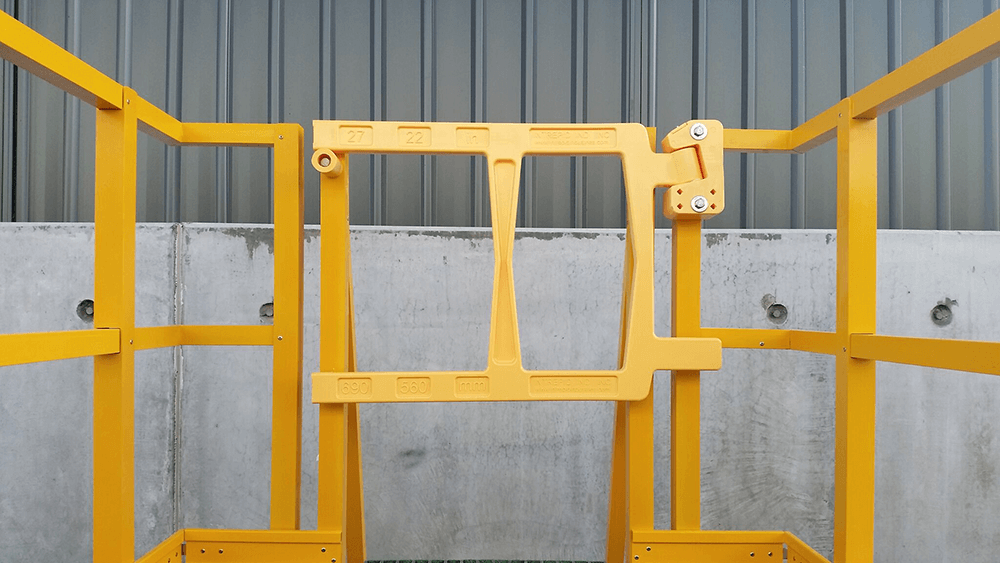

A gravity gate is a type of gate that operates primarily using gravity rather than motors, electricity, or complex mechanics. When opened or released, it closes automatically because of its own weight. Simple physics. Reliable movement. Minimal failure points.

I used to associate gravity-based systems with something outdated or temporary. But the deeper I looked, the more I realized that gravity gates are still widely used because they’re dependable. Gravity doesn’t need power. It doesn’t freeze. It doesn’t disconnect. In environments where safety matters more than convenience, simplicity often wins.

Why Gravity Gates Are Still Used Today

It started with something I thought I’d hate: reading safety documentation. Dense. Dry. Full of rules. But hidden inside those pages is a very consistent philosophy – systems should fail safely.

Gravity gates are designed with that exact principle. If something goes wrong, they default to a closed or protected position instead of staying open.

They’re commonly used in:

- Industrial facilities

- Construction sites

- Warehouses

- Temporary access points

- Elevated platforms

And this is where another phrase often appears right next to gravity gate requirements: toeboards should be at least a specific height. At first glance, that sounds oddly specific. But it’s not arbitrary at all.

The Role of Toeboards in Gravity-Based Safety Systems

Here’s where things started to click for me.

A gravity gate doesn’t work alone. It’s usually part of a larger fall-protection system. And toeboards are one of the most overlooked yet critical components of that system.

Toeboards are the low barriers installed at the base of guardrails. Their purpose is simple:

- Prevent tools from falling

- Stop debris from being kicked off edges

- Add a visual and physical boundary

Safety standards often state that toeboards should be at least a certain height – commonly around 100 mm (4 inches), depending on regulations. That minimum isn’t about comfort. It’s about physics and human movement. Feet shuffle. Tools roll. Gravity pulls downward. When gravity gates open and close, toeboards ensure that nothing unintentionally follows gravity in the wrong direction.

Why Minimum Measurements Matter More Than They Sound

I used to skim over phrases like “should be at least.” They felt negotiable. Flexible. Optional. They are not. When a guideline says toeboards should be at least a certain size, it reflects real incident data. Objects falling from height cause injuries not because systems failed completely, but because small protective elements were missing or undersized.

Here’s what proper toeboards help prevent:

- Slipping tools becoming falling hazards

- Loose materials sliding through gaps

- Visual misjudgment of platform edges

Paired with a gravity gate, they create a layered defense system. One element supports the other.

How Gravity Gates and Toeboards Work Together

This is where it all shifted for me. A gravity gate controls access. Toeboards control consequences. When someone opens a gravity gate on an elevated platform, there’s a brief moment of vulnerability. That’s when:

- Feet move closer to the edge

- Tools are repositioned

- Attention is divided

Toeboards reduce the risk during that transition. They don’t rely on behavior. They rely on structure.

This is the quiet genius of safety design – it doesn’t assume perfect people. It assumes real people.

Common Misunderstandings About Gravity Gates

I’ve seen gravity gates described as “basic” or “temporary.” That misunderstanding can lead to poor implementation.

Some common myths:

- Gravity gates are only for low-risk areas

- They don’t need additional barriers

- Any gate that swings closed counts

In reality, a true gravity gate is designed with weight distribution, closing speed, and alignment in mind. It’s not just a door that falls shut.

And without proper guardrails and toeboards – again, toeboards should be at least the recommended height – even a well-designed gate can’t do its job fully.

The Human Factor: Why Simple Systems Protect Better

Let me be honest. The more complex a system is, the more likely people are to bypass it.

I’ve watched people disable alarms, prop open doors, or remove barriers because they slow things down. Gravity gates don’t invite that behavior. They work quietly. Automatically.

You don’t have to remember to close them. You don’t have to trust someone else to reset them.

Gravity does the work. And when combined with correctly sized toeboards, the system protects not just the person passing through, but everyone below.

What I Look for Now When I See Safety Systems

After spending time understanding these concepts, I can’t unsee them. When I walk past construction zones or industrial areas, I notice:

- Does the gate close by itself?

- Is there a visible toeboard?

- Does the barrier feel intentional or improvised?

If toeboards should be at least a certain height, I look to see whether they actually are. Often, they aren’t — and that’s where risk quietly enters. This awareness isn’t about fear. It’s about literacy. Once you understand the language of safety, you start seeing the logic everywhere.

Why This Matters Even If You’re Not an Engineer

You might be wondering, “Why should I care if I don’t work on a site?”

Because these systems influence:

- Workplace safety policies

- Temporary structures at events

- Public access areas under construction

- Even playground and school design

Gravity gates and toeboards appear far beyond heavy industry. Understanding them helps you ask better questions and notice when something feels off.

Would you trust a staircase without a railing? Probably not. This is the same principle — just applied vertically and industrially.

The Bigger Picture: Safety That Doesn’t Need Supervision

The best safety systems don’t rely on constant reminders. They’re built into the environment.

That’s why gravity gates remain relevant. That’s why standards repeat phrases like toeboards should be at least instead of “if possible” or “when convenient.”

These are not suggestions. They are lessons learned the hard way.

When systems are designed to work with gravity instead of against it, they tend to last longer, fail less dramatically, and protect more people. Understanding concepts like gravity gate changed how I see everyday structures. What once felt like technical noise now feels like quiet intelligence built into space.

Safety isn’t about overengineering. It’s about respecting physics, human behavior, and small details that prevent big consequences.